There are a few situations that every contractor or carpenter most likely have faced. You are fixing a screw into a hard ply or a heavy wooden frame. The drill machine is making a loud noise and you are pushing hard. Right when you think the job is almost done, the screw slips and the head breaks off.

In that very moment, what is usually the first thought? In most cases, the screw is to blame. You might look at the broken piece and think the quality is cheap. But in most cases, the steel did exactly what physics forced it to do.

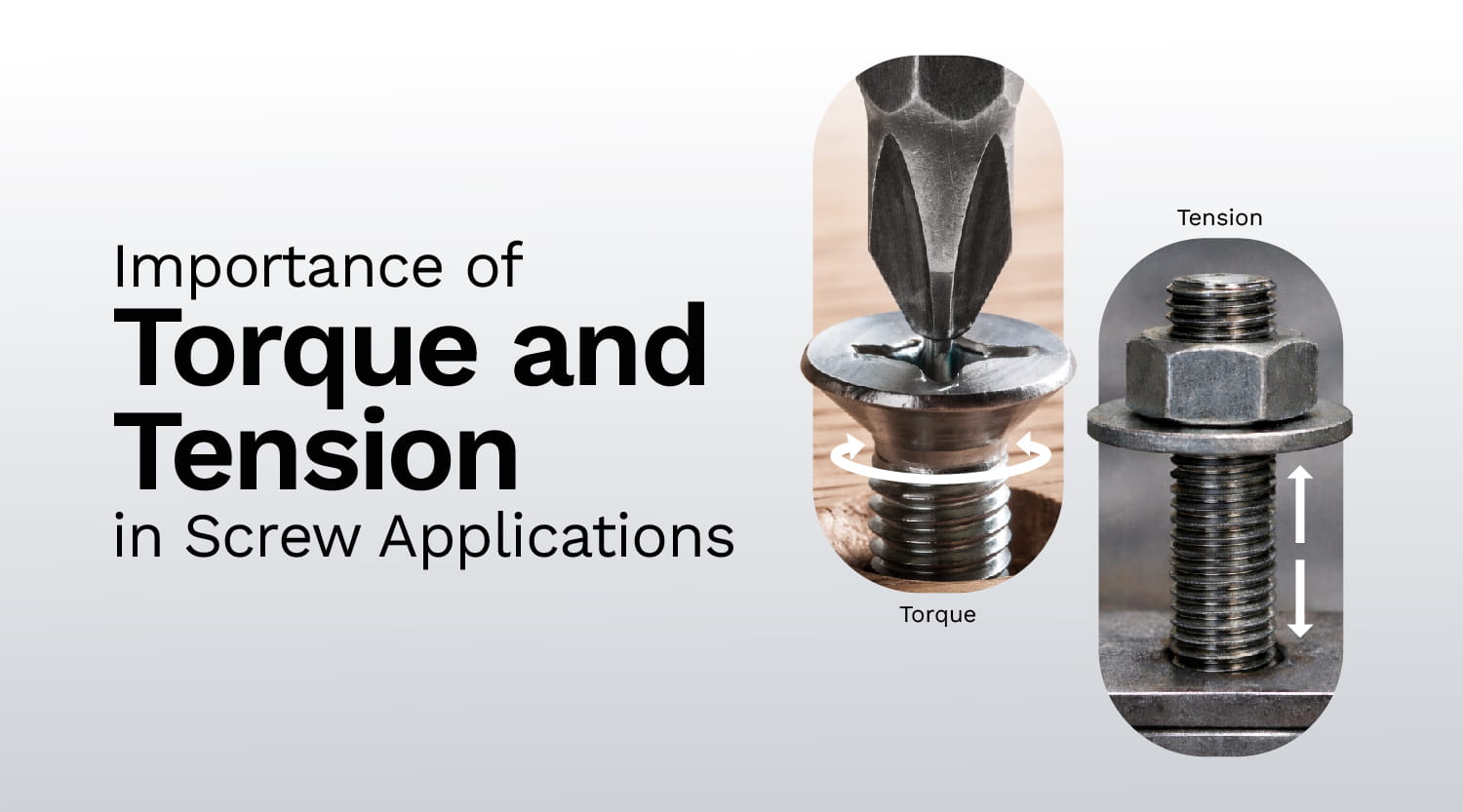

The failure usually starts with a simple misunderstanding of two different things: Torque and Tension.

In our years of manufacturing at LP Screw, we have seen this happen in factories and on construction sites across India. The operator at your site may think that ‘tighter is better’. However, applying more force doesn’t necessarily mean a strong hold. It does not work like that. In fact, confusing Torque and Tension in screw applications is the main reason why furniture joints become loose or machines start rattling a few months later.

To fix a problem, we must first understand what is happening inside the joint.

To understand this better, imagine a screw like a very stiff spring. Thus, to hold two pieces of wood or metal together, that spring needs to be stretched slightly. That stretch is the tension. It is this ‘pull back’ from the stretched metal that keeps the joint tight. Torque is just the method we use to create that stretch.

However, when you think that 100% of your torque turns into tension, that’s when things start going wrong.

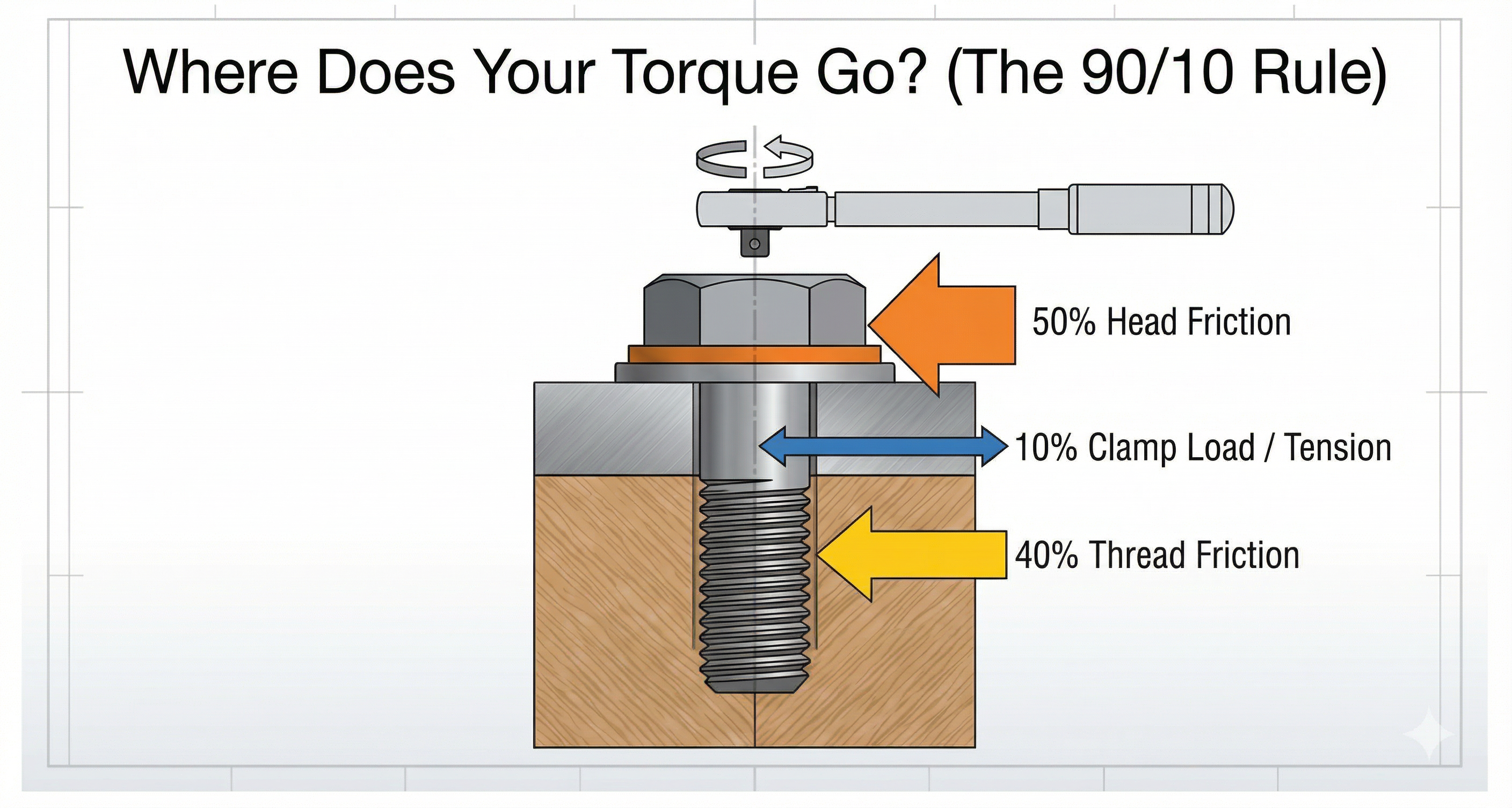

If you speak to any senior engineer or a serious SS Screw Manufacturer in India, they will tell you about the “90/10 Rule”. It is a strict reality for anyone who tightens bolts by hand.

When you apply force to a standard dry screw, only about 10% of that effort actually stretches the screw to create clamping force.

So, where does the other 90% of effort go? You will be shocked to know that it is wasted in fighting friction.

This is why Torque and Tension in Screw Applications are rarely the same number. You are mostly fighting the roughness of the metal surfaces and not actually tightening the joint.

This is where our Indian working conditions play a big role. Our project sites are not clean. There are several factors at play such as dust, moisture, vibrations etc. Be it any state in India, the problem of moisture and dust always persists. Does it ever happen that a helper leaves a packet of screws open on the floor and over two-three days, the moisture in the air creates a very thin layer of rust on the threads? It might not look like rust to the naked eye, but the surface becomes rough.

When the carpenter uses that screw, the friction increases. He applies the same force he used yesterday. His hand feels the same resistance. But because the friction is higher, maybe 95% of his effort is now being wasted on that roughness. Only 5% is left to clamp the joint.

The screw feels tight to the hand. But the joint is actually loose. As time goes on and the weather changes, the wood may expand or contract. This results in joints opening up. When this happens, your client complains about the workmanship, but only you know that the real issue was the invisible friction.

So if friction is the problem, should we just put oil on every screw?

This is the second most common mistake we see on sites. A mechanic sees a dry bolt and dips it in oil or grease to make it go in smoothly. It seems like a smart idea. It reduces the friction significantly.

But this creates a new danger. Friction may come across as a challenge, it also acts as a safety barrier. When you apply the same force to a well-oiled screw, suddenly, all that force goes directly into stretching the screw.

Because there is no friction to fight, you unknowingly over-tighten it. You stretch the metal too much. It goes past its limit and deforms permanently. In many cases, the head simply snaps off before you even realise you have gone too far. Thus, when you understand the balance of Torque and Tension in screw applications, you realise that you cannot use a dry screw and an oiled screw the same way.

The rules change again depending on what metal you are using. As a dedicated SS Screw Manufacturer in India, we often have to explain to our clients that Stainless Steel behaves differently from normal Mild Steel. Stainless Steel is softer.

It is also prone to ‘galling’ or jamming. Thus, if you use a high-speed power drill on an SS screw, the friction creates heat very quickly. The threads can get hot and fuse together. The screw gets stuck halfway. It will not go forward and it will not come back out.

The worker thinks he needs more power to push past the stuck point. But more power just breaks the screw. For Stainless Steel, the secret is slow speed and steady pressure. You cannot rush it. The feeling of tightening SS is different from the hard stop of mild steel.

To learn more about stainless steel screws, check out our blog : How to Choose the Right Grade of Stainless Steel Screw for Your Project?

You do not need expensive testing machines to get this right. You just need to follow a proper process. Here is how experienced workers ensure reliability:

A: The number one cause is over-tightening. Nine times out of ten, this isn’t a problem with cheap steel; it’s a simple case of over-tightening. If you slicked up the thread with oil or grease, you effectively removed the natural friction the screwdriver relies on. Without that friction, 100% of your muscle went into stretching the screw until it just gave up and snapped. The other common culprit is driving into super hard wood without a proper pilot hole.

A: Not always. While lubrication makes driving much easier, when you apply the same force to a greasy screw as you would a dry one, you’re going to over-tighten it by about 40%. That’s often enough to stretch the screw permanently. If you absolutely have to use oil (say, to keep rust away), you must drive it gently and stop way sooner than you normally would.

A: Stainless steel threads ‘weld’ themselves together due to friction and heat. Stainless Steel is actually softer than regular mild steel and it gets hot extremely fast when rubbed. If you blast it in with a high-speed impact driver, those threads instantly heat up and basically ‘weld’ themselves together, we call it cold welding. To fix this, you can use a slow speed on your drill and keep consistent pressure.