If you walk barefoot on a wooden deck, your feet will tell you immediately if the carpenter knew his job. If you feel sharp metal edges, uneven heads or holes where water has collected, the wrong fasteners were used. But if the surface feels smooth and continuous, it is likely held together by the right engineering.

Building for an outdoor project is a different game. During the summers, the heat expands the wood. Whereas in the monsoon the moisture swells the wood. On the other hand, the exposure to the consistent sunlight results in UV rays breaking down surface coatings.

This is why standard screws often give up after one season. They may rust or snap, sometimes even ruin the look of expensive timber. As a specialized furniture screw manufacturer, we know that along with the tight grip, high-end outdoor projects require specific tools for specific problems.

Here are the three advanced fasteners that separate a professional job from a temporary fix.

When it comes to heavy decking, boardwalks, or pool-side flooring, there is one fastener that outperforms all other screws for outdoor furniture and that’s the Carriage Bolt Screw.

You might know it as the ‘Cup Square Bolt’. While many contractors try to use heavy-gauge screws for decking, the Carriage Bolt is technically superior for two reasons: Safety and Security.

The top of a Carriage Bolt Screw features a smooth and domed mushroom head. It doesn’t have any space for a screwdriver. Also, it lacks any sharp edges. When installed properly, it is perfectly safe for children or guests walking without shoes. It prevents the common injury of toe-snagging that happens when screw heads lift up over time.

Underneath that smooth head is a square neck. When you tighten the hex nut from below, this square section bites into the wood and locks the bolt in place. It cannot rotate. This is an important feature of screws for outdoor furniture and decking. It helps in keeping the fastener stable even when the wood expands and contracts.

Available Sizes: We offer a wide range from 1/4″ x 38mm up to 125mm, ensuring you have the right length whether you are fastening a single plank or a thick structural beam.

If you are building a deck that needs to last ten years, do not rely on screws alone. Bolt it down.

While the Carriage Bolt handles the heavy timber, what happens underneath?

Most modern outdoor furniture and deck sub-structures in India are built on MS (Mild Steel) hollow pipes to prevent termite attacks. Attaching wooden planks to these metal pipes is where most failures happen. Before, you had to make three separate steps: drill a hole in the wood, then drill a hole in the metal and finally put in a screw. This is where LP’s SDS (Self-Drilling Screw) makes your life easier.

The market is flooded with low-cost imported screws that look the same but fail on the job. A standard Chinese SDS typically drills only 1.5mm to 2mm of metal. If your structural pipe is thicker, the screw burns out or snaps. Our SDS is engineered from high-grade Carbon Steel, not inferior alloys.

Drill Capacity: With a superior nib design, an LP SDS can drill through 4mm to 4.5mm thick metal which is double the industry average.

Corrosion Armor: Outdoor screws face moisture constantly. While standard screws rust very quickly, LP SDS comes with a CR6+ coating (6+ microns) that passes a 96-hour Salt Spray Test.

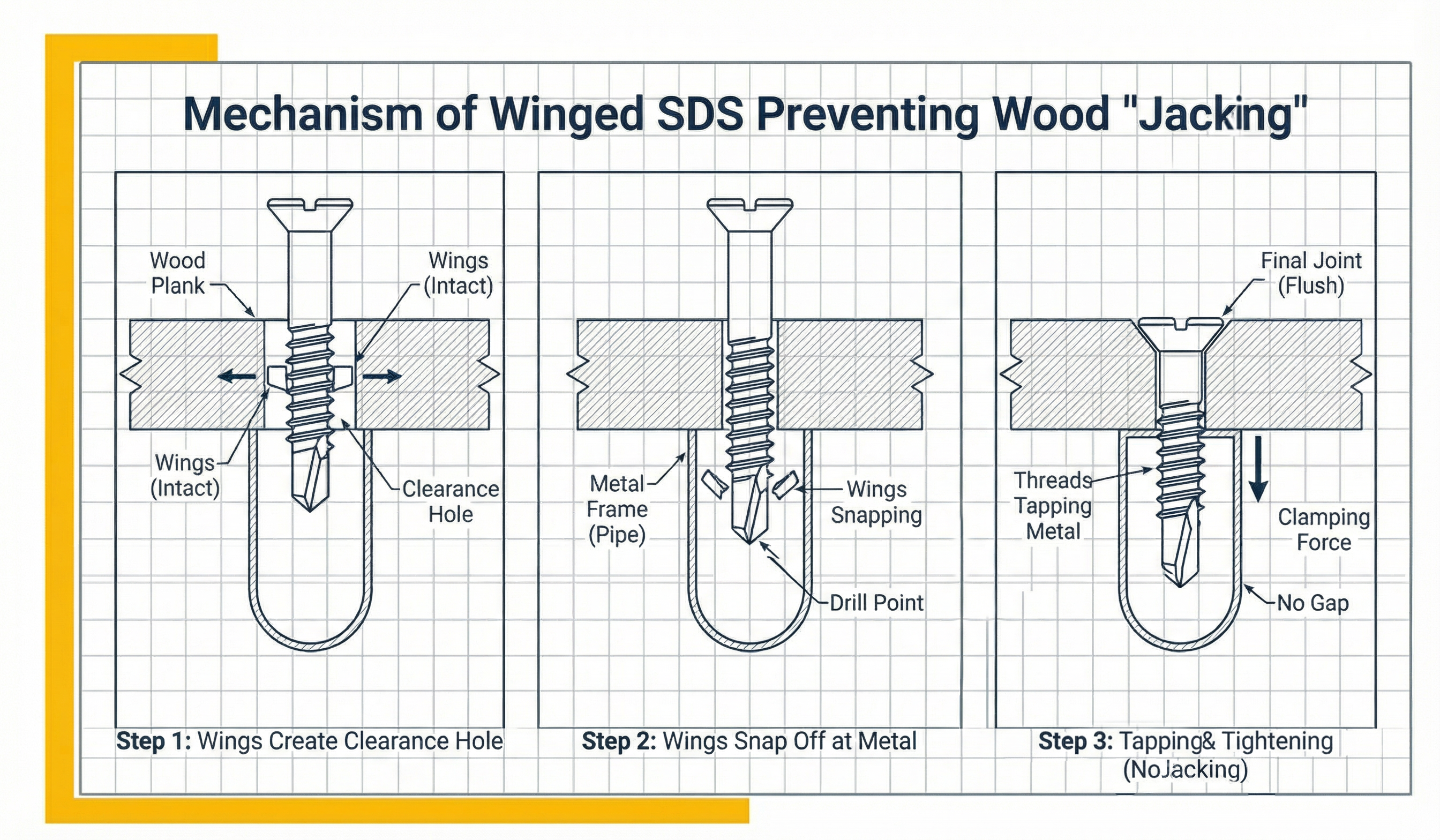

For decking, you need our specific ‘Winged’ SDS.

Pro Tip: Always look for the ‘LP’ Mark on the head. It is your guarantee of Carbon Steel quality, not a cheap imitation.

This prevents the annoying problem of ‘jacking’, where the wooden plank lifts up from the frame before the screw is tight. Using the right SDS speeds up the job and ensures a tight, rattle-free fit for metal-framed screws for outdoor furniture.

Finally, let us talk about beauty. For years, architects have complained about the ‘Silver Spot’ problem. You build a beautiful swing (Jhula) with a beautiful dark and polished Teak. It sits in a semi-covered veranda, protected from direct rain but visible to every guest. Then, you ruin the look by drilling shiny, silver stainless steel screws into the dark wood. It breaks the visual flow.

Some contractors try painting the screw heads. But as soon as the screwdriver touches the head, the paint chips off, leaving a messy finish on your most expensive furniture piece.

PVD (Physical Vapor Deposition) screws are very different from simple paintings. It is a high-tech vacuum coating process that bonds colour to the metal at a molecular level. It means the shade lasts longer. This opens up a complete design palette for your semi-outdoor hardware.

We at LP, offer a curated range of finishes to match any mood: Gold, Rose Gold and Antique Bronze for classic luxury; Matte Black, Grey and Zirconium for modern industrial themes; and even Blue and Rainbow for bold creative statements. This variety allows you to choose a fastener that either disappears into the background or stands out as a deliberate design feature.

More importantly, it adds another layer of protection. A PVD coated corrosion Resistance screw is incredibly hard and scratch-resistant. You can drive it with a power tool and the colour will not peel off.

To understand why top architects are making this switch, read our full article on how PVD finishing screws are revolutionizing the fastening industry.

We often tell our clients that the fastener is the smallest part of the budget, but the biggest part of the safety. Using a generic screw on a luxury outdoor project is a risk. Using a specialized outdoor furniture screw,whether it is a Carriage Bolt for the deck or a PVD screw for the visible joinery, is an investment.

It ensures that when the monsoon ends and the sun comes out, your work looks exactly as good as the day you finished it. We have designed this category of outdoor furniture screw because we understand the Indian environment. We know that in this industry, reliability is the only thing that matters. This is a reason why you shall always build with the right tools, because it’s not just your name but also your reputation that depends on it.

A: Please do not do this. We see this mistake on sites every day and it is heartbreaking. Those black screws are made for indoor gypsum board only. They are brittle and will snap the moment your outdoor timber expands in the summer heat. Even with paint, they will rust. Always use Stainless Steel for the outdoors.

A: Think about the people using the deck. A Hex Bolt has a sharp, raised head that can hurt bare feet or snag a saree. A Carriage Bolt has a smooth, rounded head that is safe to walk on. Plus, the square neck locks into the wood, so it won’t spin loose over time.

A: It depends on your pincode. If you are building in a coastal city like Mumbai, Chennai or Goa, then yes. The salt in the air will eat standard steel in months. For inland cities like Delhi or Pune, standard SS 304 is usually tough enough.

A: PVD is very different from normal paint. It is a bond that happens inside the metal surface. While nothing lasts forever under direct UV rays, PVD is far tougher than powder coating. It will keep that premium look for years, long after painted screws have peeled.