Sale is not everyone’s cup of tea. Selling something has to do a lot more about establishing the trust first, and then actualling selling a product to the prospect. You may push a product once or maybe twice, but unless your product has a substance, no price or packaging can help you bring back your customers. In a hardware business, trust is built by small things that matter a lot.

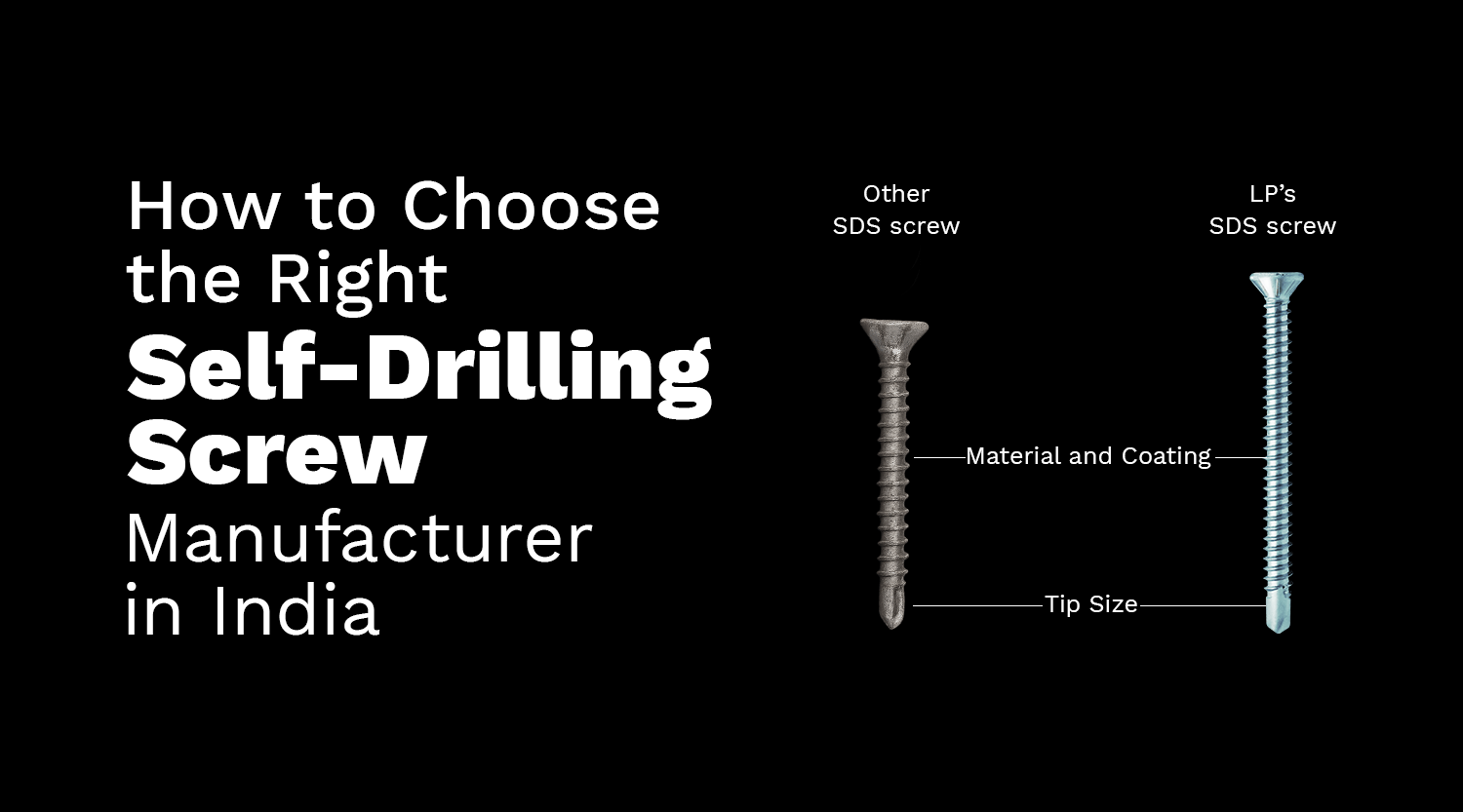

One such tiny detail is the self-drilling type of screws. These screws are used for fastening metal sheets, roofing panels, and structural frames without the need for a pilot hole. They save time, reduce effort, and ensure clean finishes when chosen right. But when the quality drops, the complaints pile up fast.

With this blog, we will be helping you whether you are a dealer, distributor or hardware store owner in choosing the right self-drilling screw manufacturer in India. So that’s what you sell today… doesn’t cost you your credibility tomorrow.

Margins matter a lot. Margins decide which product will successfully get the shelf space, and which ones will not be considered at all. Margins ensure the sustainability of any business. However, when it’s about establishing long-term credibility, margins alone can’t be the sole driving factor. There are many parameters at play you need to consider.

If a wood screw bends with minimal effort, breaks while drilling, or rusts just within a few weeks, your customer will come back. But not with a new order, with a set of complaints to deal with. If this happens too often, they won’t just stop buying that brand, they might stop buying from you altogether.

So yes, compare prices. But always ask yourself: Is the rate low because the quality is smartly optimized? Or is it low because the brand is cutting corners you’ll end up paying for later?

To ensure that screws are consistent, you can start by checking whether the screw quality uniform across batches? Whether the heads chip during drilling? Whether the threads are sharp and clean, or do they feel rough and unfinished?

While choosing self-drilling screws, even tiny variations such as the drill point angle or flute depth can impact the fastening and may crack the panel. When your customers are working on-site, they don’t have the time or patience to deal with stuck screws or split boards. That’s why, when finalising a self-drilling screw manufacturer in India, consistency in quality is the bare minimum that you shall ask for and not compromise in it at any cost.

Another important and very crucial mistake that can cost you a lot is going by the labels blindly. While finalising your self-drilling screw manufacturer in India, don’t just trust what’s written on the box. Instead, you can ask the supplier about the signs that show that their brand is serious about quality. See if screws are grade-marked? Is there any salt spray or torque testing data to support their corrosion or strength claims? These things may feel small, but they go a long way in protecting your reputation.

If a CSK Phillips screw breaks mid-job or rusts within a month, the problem doesn’t stay with the brand, but it will come straight back to your counter. A good manufacturer knows this and never leaves quality unchecked across batches. Thinking about this can save you a lot of trouble later.

As a supplier, you may be catering to a different set of buyers such as contractors, carpenters or industrial clients. How the product is packed makes a big difference. Check whether the screws are packed in a way that keeps them organised, rust-free and easy to count. You can also check whether they come in retail-friendly packs or only in bulk cartons.

A reliable self-drilling screw manufacturer in India will always offer smart packaging options that suit both shop displays and on-site convenience. When a carpenter opens a box, they should see usable furniture screw and not chipped heads, rusted tips or a pile of confusion. The way the screws are packed speaks volumes about how the brand sees your business.

Your job doesn’t end once you have received the first batch of screws. When something goes wrong or even when a buyer has a small doubt, it always helps to have a brand that listens and responds in time. A good self-drilling screw manufacturer in India won’t wait for you to chase them. They’ll reach out to you, check on your inventory, take restocking orders in advance and ensure the goods arrive on time, in good condition, without the need for repeated follow-ups.

This kind of proactive support matters more than you realise. It ensures fast-moving inventory doesn’t get stuck. It keeps your shelves full and your customers satisfied. Most importantly, it saves you time, so you can focus on growing your business instead of resolving issues that can be avoided easily.

This is what makes LP Screw special. From dispatch to delivery, from technical clarity to partner care, LP Screw gets it right, every single time. And that’s why dealers across India trust LP Screw not just as a screw supplier, but as a brand that always has their back.

Because once you’ve found a partner like that you stop worrying about the backend, and start building your name out front.

Built on Trust. Delivered Without a Follow-up.

At LP Screw, we’ve kept things simple. We make a good product, deliver it on time and stay in touch. We don’t wait for reminders. We follow up, check your stock, and make sure your orders reach you in the right condition, every time. That’s why dealers across India trust us. Because in this business, it’s not just about the furniture screw. It’s about the people who stand behind it.

If this blog helped you think about screws and suppliers a little differently, chances are you’ll enjoy what we share next. We post tips, stories and small insights like this every alternate week, all designed to make your work smoother, smarter and a little more satisfying. Follow us on social media to stay in the loop and never miss an update from us.