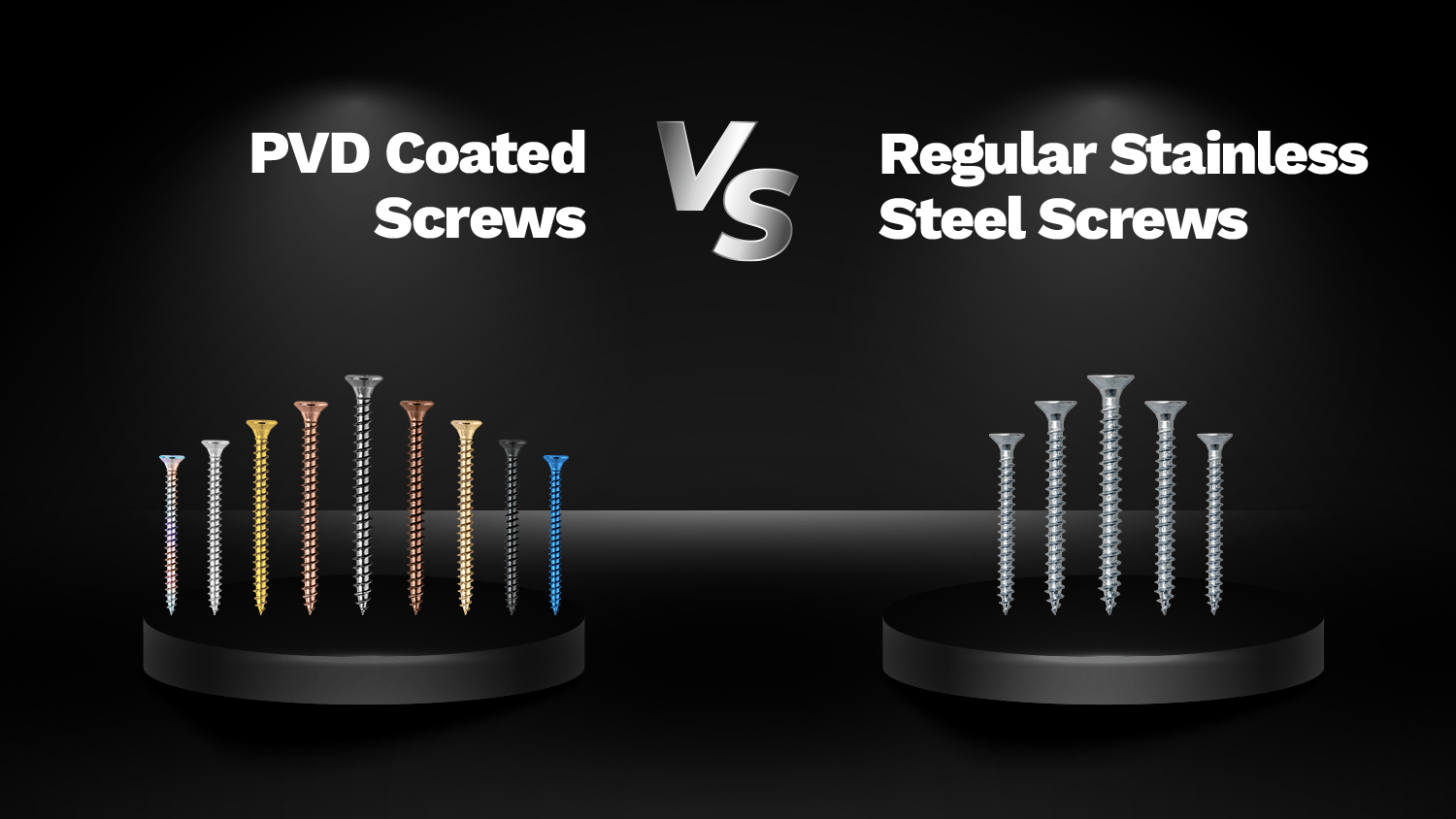

PVD Coated Screws are like a much needed upgrade to the world of fasteners. These screws changed the way professionals use fasteners. For decades, people were compelled to rely on regular stainless steel screws even for strength and corrosion resistance. While regular screws have served well all these years, whenever projects demanded both performance and aesthetics, stainless steel screws were sort of a disappointment for the carpenters, DIY enthusiasts and other end users alike. This is a reason why PVD screws became popular. These screws offered toughness along with a finish that lasts and looks premium.

In this blog, we’ll break down the real differences between PVD coated screws and regular stainless steel screws and explain where to use which type of screw for the optimum performance. This will help you decide when to invest in the smart upgrade.

So, the literal meaning of PVD is Physical Vapor Deposition. But don’t worry, we will simplify it for you. It’s a process that allows the deposition of thin, hard film on the surface of the screw at the molecular level. You may wonder if it is like electroplating or a paint. Well, unlike paint or electroplating, it doesn’t peel or chip away. Instead of that, it forms a strong shield. This protective shield not just resists scratches and stains, but also fights off corrosion, even in coastal or high-moisture areas. Apart from these functional aspects, there is another angle of aesthetics. These screws come in a premium decorative finish in colours like gold, bronze, black, rose etc.

This is a reason why when you have a look at luxury interiors or high-end furniture, it is very likely that you will be able to see the PVD screws used in such projects. The protective coating makes these screws more durable and reliable.

Now, stainless steel screws (grades like 304 or 316) have been trusted for decades. They’re strong, they fight corrosion decently and they’re affordable. You’ll find them in kitchens, construction frames, railings and every kind of machine screw application in factories.

But the key problem with these screws is that the bare stainless steel scratches easily. It loses its shine over time, especially if exposed to weather, moisture or heavy wear and tear caused due to rough handling. So even though the screws made of these are dependable for utility, it lacks the premium appeal that designers and architects often look for.

| Feature | PVD Coated Screws | Regular Stainless Steel Screws |

| Finish & Aesthetics | Available in gold, bronze, black, rose, with brushed or mirror finishes. Perfect for premium looks. | Limited to plain silver polish or brushed finish. |

| Scratch Resistance | The hard surface resists scratches and stains. | Scratches and dull spots show easily. |

| Corrosion Resistance | Enhanced resistance + stainless base. Ideal for coastal/high-moisture areas. | Good resistance but weaker in harsh outdoor or marine conditions. |

| Maintenance | Easier to clean; hides fingerprints. | Needs frequent polishing and cleaning. |

| Cost | Higher upfront, but lasts longer and keeps its look. | Cheaper initially, but wears faster. |

| Applications | Luxury furniture, elevators, cladding, architectural interiors. | Industrial kitchens, piping, basic frames, general machine use. |

Imagine installing a stunning glass railing with plain silver screws that start showing scratches within months. Doesn’t work, right? PVD coated screws let you try different combinations of the colours that can seamlessly integrate in your design, whether it’s gold, black, copper, rose etc. This has truly changed the way screws are used in the present day projects such as modern interiors, heritage-inspired projects etc.

Regular stainless steel performs fine in kitchens or industrial settings. But when it’s outdoor cladding, luxury facades, or fittings in coastal cities, PVD coating adds that extra layer of protection against weathering.

Anyone who has maintained stainless steel knows the story — constant wiping, polishing, and still those stubborn fingerprints and stains. PVD screws are easier to clean and stay glossy with just an occasional wipe.

Yes, it may appear that these screws cost more upfront. But if you’re investing in PVD screws for premium projects, you’re buying peace of mind. Less maintenance, fewer replacements, and a finish that lasts years.

The Indian screw market is flooded with options. But not every PVD screw delivers what it promises. Some look good for a few months and then fade or scratch. This is why choosing the right manufacturer matters.

As a trusted PVD screw manufacture in India, LP Screw ensures:

When it’s about projects that carry your name, your craft and your reputation, LP’s PVD screws give you confidence that lasts.

We hope that the debate of PVD Coated Screws vs Regular Stainless Steel Screws can be considered settled. If it’s about structural strength, utility or there are budget constraints, stainless steel is a reliable and affordable option for you to consider. Whereas, if you are looking for that premium appeal, various colour shades to choose from the PVD coated screws are your go to choice. Additionally, these screws can withstand harsh conditions which makes them worth every rupee that you will be spending.

At the end of the day, a screw may feel like a tiny detail, almost invisible. But talk to any architect or contractor and they’ll tell you that it’s these details that shape the final impression. That’s why PVD coated screws are loved in premium projects. With multiple shade options, they don’t fight the design, but they blend right in. They deliver strength, elevate the look of your project. So what once used to be considered as a nuisance, is now looked at as a detail that enhances the design itself.

FAQs:

Q: What are PVD coated screws?

A: PVD coated screws are stainless steel screws with a thin, hard PVD (Physical Vapor Deposition) coating that enhances durability, scratch resistance, and looks.

Q: Are PVD coated screws superior to stainless steel screws?

A: Yes. Unlike stainless steel screws that are solid, PVD coated screws endure longer, are scratch resistant, and are available in high-end finishes such as gold, matte black, copper, blue and many more.

Q: Where are PVD coated screws applied?

A: PVD coated screws are used in luxury furniture, interior architectural work, elevators and cladding applications where you want to achieve great visual appeal along with the strength.

Q: Are PVD coated screws more costly than stainless steel screws?

A: PVD coated screws may cost more initially. However, in the long run, the cost offsets, they are more durable and require less upkeep. Also, their finish lasts longer as compared to stainless steel screws.

Q: Are PVD coated screws suitable for outdoor use?

A: Yes. PVD screws are extremely resistant to corrosion, water and salt, which is the reason why they are perfect for outdoor projects, especially in the coastal areas.