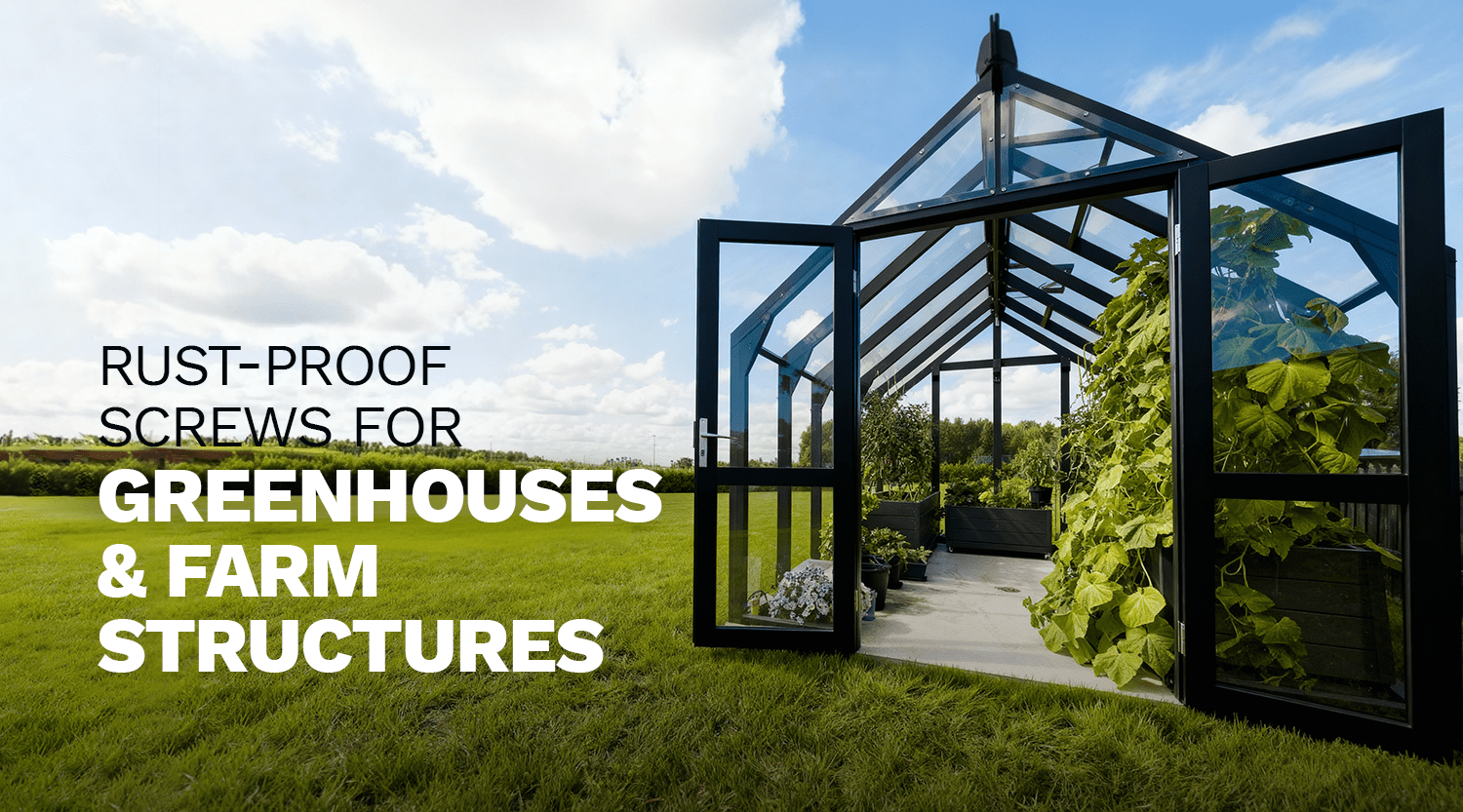

Rust-Proof Screws is a detail that often gets unnoticed, but in today’s ever evolving world of new age farming, they hold everything together, quite literally. When you step inside a modern greenhouse on a misty morning and you’ll see it: droplets forming on the steel frame, sensors blinking under the canopy, irrigation lines glistening with humidity. Beneath this controlled chaos, the joints, panels and even the frames are fastened together by screws that last.

There was a time, when the agrarian success was linked with the acreage i.e. how many acres you own and cultivate at once. However, today agriculture is not defined by the acres, but it’s the precision that leads the way of agricultural success. From hydroponic systems cultivating exotic produce to the vineyards & avocado farms, needing the structural supports, screws play a crucial yet significant role. With this blog, we will be learning how screws in the agricultural set up can contribute to the success of new age farming.

All of us know how the agricultural landscape in our country has been transforming since the past two decades. As well-educated and tech-savvy young individuals have started showing interest in farming, the sector has witnessed quite a few positive surprises. With the advent of technology, tools such as soil sensors, automated irrigation systems, controlled-environment structures have been widely used by these new agriculturists who are growing premium crops. Many of such crops are grown exclusively to cater the export market or high-end domestic markets.

The experiments in the climate-smart farming models are groundbreaking too. Pioneered by organisations such as Kheyti, the modular greenhouses and shed-net houses protect crops from unpredictable weather. Their infrastructure not just withstands heat and humidity but also deals with the constant exposure to water misting, fertilizers and temperature variations precisely. In such a set up Rust-Proof Screws have an essential significance which is to endure the conditions that are way too different from normal.

A greenhouse or farm structure is continuously exposed to moisture, condensation and chemicals. Ordinary fasteners may lose their sheen quickly resulting in the weakening of joints and rusting of frames. This may eventually compromise the structural integrity. In hydroponic setups nutrient-rich water circulates through PVC channels and metal supports. This is why corrosion can spread very rapidly even if there is slight negligence towards the maintenance.

That’s why a Corrosion Resistance screw is not just an upgrade. They are a necessity in such setups. They protect steel frames and anchor joints. They even help in maintaining the design stability of shade-net houses, trellises and drip-irrigation supports. Each screw resists the elements while preserving alignment and strength, ensuring that the farmer’s investment lasts season after season.

At LP Screw, when we say ‘rust-proof’ it isn’t just a hollow claim. It is a result of rigorous tests. As a leading stainless steel screws manufacturer in India, our R&D team has tested these fasteners in challenging conditions. They meet the demanding requirements of modern agriculture.

The surface finishing used in LP screws enhances the durability of the screws. It also prevents oxidation. The thread geometry allows smooth drive-in and reduces the friction, without causing any surface damage. For metal or treated wood installations the coatings of our screws provide adequate support. The design precision ensures uniform torque and consistent seating, essential for greenhouse fabrication and frame assembly.

In simple words, our Rust-Proof Screws are built for environments where exposure is constant and reliability non-negotiable.

In greenhouse construction, every joint matters. Panels, aluminium channels, clamps, and structural connectors all rely on fasteners that can handle humidity, nutrient mist, and temperature swings. Rust-Proof Screws for Greenhouses maintain grip and alignment even after years of use.

They’re ideal for:

Our screws ensure a consistent hold and clean appearance, even in the toughest climatic conditions.

Explore: Choosing the Best Rust-Resistant Screws for Outdoor & Metal Hinges

Greenhouses are just half the part of the story. The conditions outside the covered farming spaces are even harsher. The rain, soil moisture and temperature extremes can demand corrosion resistance that is tested. This is true for the farm structures like grape trellises, avocado plant supports, solar dryer frames and pump enclosures.

The stability of these structures means everything to a farmer. For farmers who are cultivating export-grade grapes or avocados, where crop uniformity and protection are important, these screws become part of the quality equation unseen, but indispensable.

A structure’s longevity depends as much on its fastening system as on its framework. LP’s Anti Rust Screws help ensure that:

It’s not just about preventing rust but also about protecting the precision of the design. Whether the structure supports a hydroponic lettuce line or a weatherproof grape trellis, a stable fastening system maintains the efficiency and safety of the entire setup.

Here are a few things that you can pay attention towards to get the best results:

Simple steps like these enhance the life of both the fastener and the frame.

At LP Screw, every batch of Rust Proof Screws undergoes salt-spray as well as the torque test. Other essential parameters such as dimensional accuracy and coating integrity are also monitored at every stage. This gives farmers, builders and greenhouse designers the assurance about the strength of the structure. At LP Screw, it’s the consistency that defines trust.

In an agrarian economy like ours, the new age farming methods are a new hope. The greenhouses, shed-net houses and new age crops are stepping stones into strengthening farmer’s income. In greenhouses, farm structures or hydroponic units, its strength ensures continuity and reliability. For India’s new generation of farmers; the ones growing smarter, cleaner and more sustainably, it’s a feeling of contentness for us to be able to contribute to this silent revolution in a small yet meaningful way.

FAQs

Q1. Why are Rust Proof Screws important for greenhouses and farm structures?

Inside a greenhouse, the consistent exposure to humidity and chemicals can pace the rusting process. Rust proof screws can ensure a strong resistance in such setups.

Q2. Are Rust Proof Screws better than galvanised ones for farm structures?

Yes. Galvanised screws can resist rust at surface level, however SS rust proof screws can resist rust at the core. This is why they are best suited for farm usage.

Q3. How often should fasteners in greenhouses be checked or replaced?

Just like you inspect your plants regularly, you can also check screws if they have changed its colour or got loose. If so you can immediately replace it with a new rust-proof one.

Q4. Can Rust Proof Screws be used in both metal and wooden greenhouse frames?

Yes. They hold well in both materials. Feel free to choose from LP’s wide range of screws.