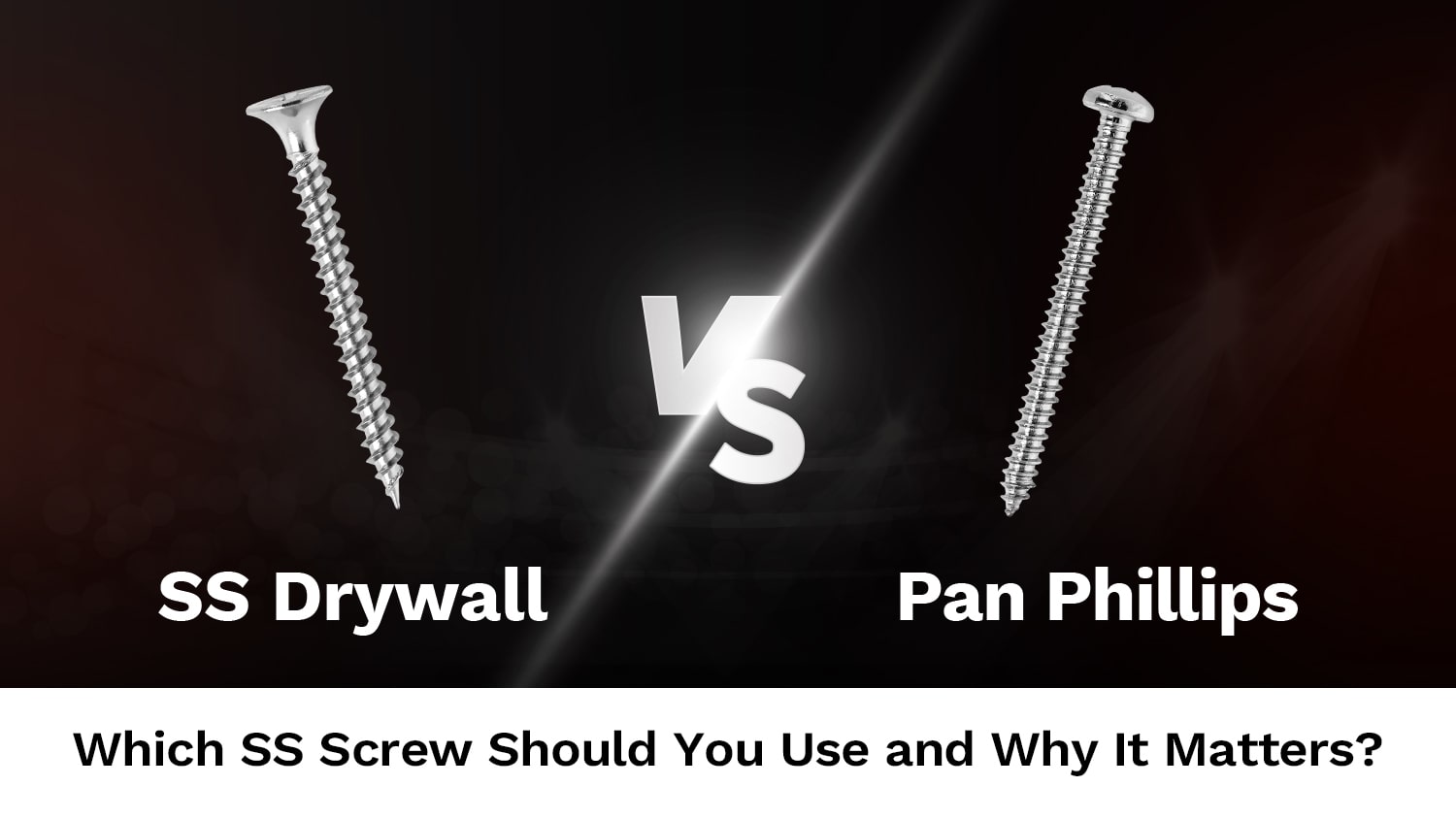

SS Drywall vs. Pan Phillips; it sounds like a quiet technical debate. But do you know that the SS Drywall screw was built to sink cleanly into the surface? On the other hand, the SS Pan Phillips screw was meant to stay visible and hold firm. Clearly each of these fasteners was designed to serve a specific purpose.

However, on different jobsites these screws are still swapped, mixed and used incorrectly. This is a reason why you see jobs go wrong. The rust spots on ceilings, cracking of wooden surfaces, loose cabinet doors and the list goes on. Watching a good project turn bad, simply because of using the wrong screw is disheartening. Your efforts, valuable time and resources go into vain.

So, in this blog, we’ll learn how these screws are designed for entirely different surfaces, pressures and torque behaviours. Even when you walk into a hardware shop, you’ll find them placed side by side, looking almost the same.

One hides under paint, the other shows its head and that subtle difference can decide whether your project lasts five months or fifteen years. One small choice that separates superior craftsmanship from an endless correction loop.

As we continue to learn further in this SS Drywall vs. Pan Phillips debate, lets understand a few key differences among these screws. An SS Drywall screw features a bugle-head. It is a drywall fastener that is designed to sink into a gypsum board. What’s special is that it protects the board without tearing it. The bugle head and the thread geometry spread load across plasterboard and bite well into wood or metal studs.

On the other hand, a Pan Phillips screw features a rounded, flat-bottom pan head and a Phillips cross recess. It is built to sit above the surface. Its application offers a tidy visible finish which is a reason why it is usually chosen for applications where the visible appearance of screw head is not a big deal or would not ruin the aesthetics of the project.

Quick fact: When corrosion and environment matter, stainless grades (SS304, SS316) keep screws from rusting and staining the wall or fixtures.

| Feature | SS Drywall Screw | Pan Phillips Screw |

| Head profile | Bugle, sinks slightly into gypsum | Rounded pan, sits above surface |

| Best for | Drywall, gypsum, metal studs | Visible fixings, cabinetry, brackets |

| Bearing area | Wide bearing surface prevents pull-through | Smaller but thicker head increases torque strength |

| Typical thread | Coarse/bugle thread for grip | Coarse or fine depending on application |

| Anti Corrosion Options | SS 304 / SS 316 or protective coating | SS or coated carbon steel |

| Common fail | Pop-out, pull-through in case of wrong size is used. | Head stripping or rust if wrong grade |

You can opt for SS Drywall screws for partition framing, ceiling channels and gypsum boards where you need a clean, flush finish without damaging the surface. The bugle head spreads pressure evenly, letting the screw sink slightly without tearing the paper layer of the board.

When fixing metal brackets, electrical junction boxes, or furniture components where the head remains visible you can choose a SS Pan Phillips screw. The rounded top sits proud of the surface, offers easy tool access and gives a neat mechanical look.

Precision is all about understanding what fits where. Even a small choice like this can decide how long your work speaks for you. With this understanding, you can save hours of rework. It allows you to make your installation look intentional rather than improvised. And if torque control is a concern, consider Torx drives. They grip better, reduce wear on tools, and let you drive stainless screws faster without stripping the recess.

| Parameter | Typical values |

| Common stainless grades | SUS304, SUS316 |

| Standards | ISO 14583, ISO 10642 |

| Length range | 3 mm — 200 mm (typical drywall 25–50 mm) |

| Head types | Bugle (drywall), Pan, CSK, Truss |

| Drives | Phillips, Torx, Security Torx, Square |

If your job is indoors and painted, zinc-phosphate coated carbon screws can work. If the panel is exposed to moisture or salt air, go stainless. Pan heads in stainless steel are great for visible fixings; but for gypsum, the bugle shape remains the most practical shape to avoid ripping the board.

The SS Pan Phillips screw is widely used in electrical panels and furniture for its neat, visible finish. However, it’s important to match the stainless grade to the environment. In damp areas or coastal sites, use SS316 to resist corrosion and prevent rust stains. Even the best screw can fail if the grade doesn’t suit the exposure. Getting this detail right is what keeps good work looking good for years.

| Screw type | Driver bits | Power tool | Pilot hole? |

| Bugle drywall | Phillips or Torx | Drill/Impact

(low torque) |

Usually no for wood studs;

yes for metal |

| Pan Phillips | Phillips bit | Drill/Impact | Depends on material |

| CSK Torx (countersunk) | Torx bit | Drill/Driver | Yes for precise sink |

When you need reliable volume supply, material certification or original PVD coatings, it’s wiser to work directly with a leading SS Drywall Screw manufacturer in India rather than a generic hardware vendor. A certified factory can provide test reports (EN 10204 / 3.1), tensile and hardness data and surface finishes such as PVD, zinc–nickel etc. that are matched precisely to your project’s needs.

At LP Screw, every batch is engineered with consistency that professionals trust. A wide variety of applications such as gypsum installations, furniture fittings and structural framing; our screws are trusted by the skilled craftsmen.

However, our vision goes beyond fastening. We make screws that bring precision, add beauty, and help build lasting projects across materials and applications.

We see screws not just as fasteners, but as crucial enablers that protect the integrity of design. Our screws combine strength and aesthetics details. Our screws define quality. That’s why builders, contractors and OEMs rely on LP Screw. Because every turn of the driver carries our commitment to craftsmanship that lasts.

One small shift in awareness about choosing the right head shape and stainless grade can turn an ordinary installation into lasting craftsmanship. At LP Screw, we put in every effort to ensure that this thinking reflects in our product. Our joy lies in facilitating the creation of outstanding projects that are created using our LP screw.

When builders, DIY users, carpenters, and craftsmen achieve the results they aim for with reliable fastening and clean aesthetics, we see it as a shared win and it motivates us to innovate and deliver, every single time.

We hope you found this blog useful. Feel free to check our blog section for more insightful reads. The variety of topics ranges from choosing the right screws, understanding materials, improving installation techniques and many more. Do consider following us on our social media handles to stay updated with the latest tips, announcements and insightful reads like this.

Can I use a pan Phillips screw for fixing gypsum board?

You can in a pinch, but pan heads sit above the board and risk pulling through thin gypsum. Bugle-head drywall screws are designed for gypsum and reduce tearing and screw pop.

Why choose stainless steel for drywall in bathrooms or coastal sites?

Stainless (SS304/SS316) resists corrosion and staining. In salt-air or wet conditions, it prevents rust streaks and long-term weakening.

How do I avoid stripping the screw head while driving?

Use the correct, fresh bit, keep the driver square to the screw, and use torque control. Consider Torx drives for heavy torque tasks, they reduce cam-out.

What’s the difference between CSK Torx and security Torx?

CSK Torx is a countersunk Torx for flush finishes; security Torx includes a pin and needs a matching tamper-proof bit to remove, useful for public fixtures.

Where can I order bulk SS drywall screws with certificates?

Contact a certified drywall screw supplier in India or factory listing ISO/EN test certificates. Ask for manufacturer test reports and delivery timelines before placing bulk orders.