It starts with a dot. You just spent lakhs on your interiors. The Gypsum board is seamless, the POP cornices are crisp and that expensive Royal emulsion paint looks flawless. Your contractor has done a great job and everything feels perfect. Then, the first monsoon hits. You look up at that white ceiling and see a tiny, brownish-orange spot. You ignore it and after a week there are three more dots just like this and then, a hairline crack appears near the AC vent.

The Gypsum was top-tier. The channel framing was galvanized. The paint was premium. The crew who put it all together, they were the best! So, what went wrong?

The problem is the one thing you never checked and it is the screw. In 90% of Indian homes, the ‘Black Screw’ is the default setting. It is cheap, it is everywhere, and quite frankly, it is a liability. As our homes get more airtight and our cities get more humid, this default choice is failing.

Let’s talk about why upgrading to stainless steel Screws for False Ceiling grids is a smart idea and how it saves you from future worries.

To fix the problem, we first have to understand the material. In the Indian retail market, the widely chosen screw for false ceilings is the Black Phosphate Drywall Screw. These are made of hardened Carbon Steel with a thin conversion coating. While they are the industry standard, it comes with an engineering limit. This is because Phosphate is primarily a ‘storage coating’. Its main function is to prevent the screw from rusting while it sits in the box or on the shelf. It performs exceptionally well in dry climates.

However, in coastal regions or during the intense monsoon season, the moisture becomes a crucial challenge. On the other hand, for a new construction site, the moisture trapped during wet masonry work speeds up the rusting of the standard phosphate layer. Thus, when a black phosphate screw is used to install the support plates or metal channels for a false ceiling, it is exposed to stagnant and humid air. As this type of coating is not designed for aggressive corrosion resistance, the rusting starts quickly. The rust spots that you see, it all starts at this point.

This is where the industry is seeing a structural shift. Leading architects and mindful contractors are moving away from the ‘default black’ options and switching to stainless steel Screws for False Ceiling applications.

The reason is simple metallurgy. Unlike a surface coating that can chip, Stainless Steel (specifically SS 304 and SS 316) relies on Chromium. When oxygen hits the surface, this Chromium forms an invisible, self-healing shield known as a ‘passive layer’. This protection is built into the metal itself. You can scratch it, torque it, or drive it into a metal channel, it simply will not rust

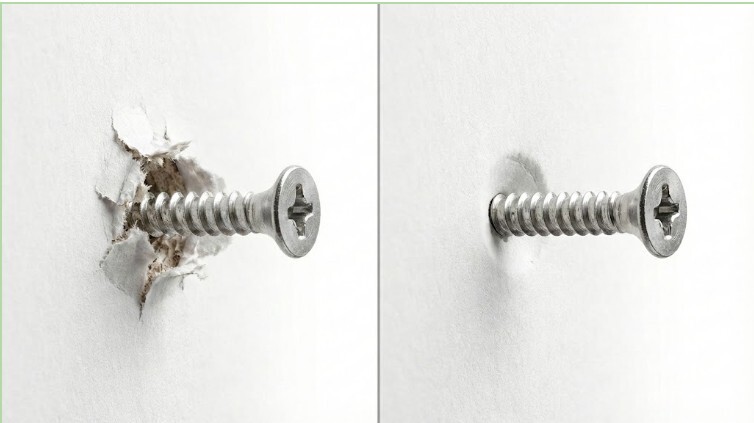

In theory, every drywall screw has a Bugle Head. However, cheap screws often suffer from ‘burrs’. These are tiny, rough metal edges under the head caused by worn-out machinery.

When you drive these, the burrs act like a saw blade, shredding the gypsum paper. At LP Screw, we maintain strict SOPs to ensure the smooth trumpet curve. This allows the head to compress the paper without cutting it. It is critical for keeping the board tight against the ceiling channel

This is the most annoying mistake we see on sites. When a helper runs to the hardware shop and asks for ‘1-inch screws’ and if he is unaware about the minute details, the shopkeeper hands him a Chipboard Screw. They look similar, but using them in a false ceiling is a disaster.

Drywall Screw VS Chipboard Screw isn’t a debate. It’s more like a Physics and application effectiveness question. For metal framing, a Drywall thread can be a perfect choice for you.

Installation Science:

The Dimpler

You can buy the best stainless steel Screws for False Ceiling, but a bad carpenter can still ruin them. Thus, ‘Over-Driving’ is a key problem in this kind of application. The gypsum board is held together by the paper on its face. That paper provides the tension.

When the drill torque is too high, the screw head punches through the paper and buries itself in the chalky core. Congratulations, that screw is now useless. The board is loose.

Solution:

Even the best SS Screws for False Ceiling applications rely on correct installation torque. If the screw head punctures the paper face, the board loses its primary structural hold.

Standard practice on premium sites involves the use of a ‘Dimpler Bit’ (Depth Setter). This tool ensures the screw stops exactly flush with the board, compressing the paper rather than tearing it. It eliminates manual error and guarantees that every fastener holds its full load without damaging the gypsum core.

So, where do you buy the original screw that can be trusted? The Indian market is flooded with self declared ‘Commercial Grade’ screws. There are traders who sell screws by weight and not specs. You may get a box that says ‘SS’, but it has so much iron in it that a magnet sticks to it.

This is why you need the best drywall screw supplier in India who sells by specification.

The LP Promise

We believe in radical transparency.

It is strange how we budget. We spend extra for ‘Marine Ply’. We pay a premium for ‘Washable Paint’. But for the screws, the only thing holding tons of material over our heads and we settle for the cheapest black option? The price difference between a standard phosphate screw and a stainless steel upgrade is marginal when viewed against the total value of your interior. Yet, the cost of rectification where you have to go through the process of scraping, re-plastering and repainting a rusted ceiling becomes significantly higher.

For the discerning homeowner and the professional contractor, the choice is clear. A false ceiling is designed to be a permanent fixture; it deserves a permanent fastener. Choose the engineering that ensures your ceiling remains as flawless in a decade as it is today.

FAQ

Q: Can I use black screws in the Bedroom and SS in the Bathroom?

A: Absolutely. That is smart budgeting. Bedrooms in dry cities (like Delhi) are fine with SS 304 or even high-grade coated screws. But for Bathrooms, Kitchens, and Balconies? Never compromise. Use SS 316.

Q: How do I know if the contractor brought real SS?

A: Use the Magnet Test. High-grade SS 304 and 316 are largely non-magnetic. If your magnet sticks hard to the screw, it’s either carbon steel or a very low-grade alloy. Also, SS is silver. If it’s black, send it back.

Q: My contractor says black screws grip better. Is he right?

A: No. Grip comes from the thread shape, not the color. He might prefer black screws because they are harder (easier to drill fast). Stainless is softer and needs a steady hand. But for long-term hold? SS wins because it won’t rust away.

Q: Can I paint over the Stainless Steel head?

A: Yes. Since SS doesn’t rust, it won’t bleed through the paint. The painter fills the “dimple” with putty and paints over it. Five years later, that spot will still be white, not orange.